Ultra-Precision Micro-Molded Plastic Parts

Micro-Injection Molding and Digital Manufacturing for Extremely Small Plastic Components

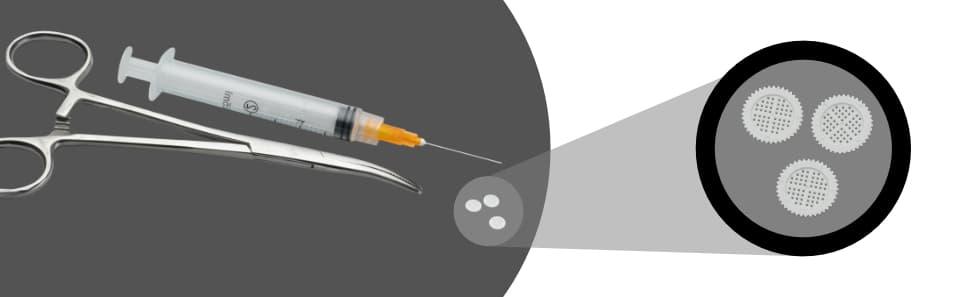

Diversified Plastics, Inc. (DPI) delivers ultra-precision micro-molded plastic parts for a range of markets. These parts are highly engineered with intricate geometries and features that are difficult and expensive to manufacture by other methods. DPI’s extensive experience with tight tolerances, difficult-to-manufacture parts, micro-molding materials and process validation helps customers get to market faster with the highest-quality parts. Micro-molded parts are used in medical device, electronics, industrial and other applications, including:

- Catheters

- Diagnostic systems

- Drug delivery devices

- Glucose monitoring

- Fiber optics

- Micro-drive systems

- Optical and hearing components

- Surgical instruments

- Wearables

- Micro-optics

- Micro-fluidic chips

- Telecommunications equipment

- And more

What Is Micro-Injection Molding?

Micro-molding is a specialized manufacturing process that differs significantly from conventional injection molding. One main difference between micro-molding and traditional molding technologies is the shot size and the precision of the injection molding machines. Micro-molding injection molding machines use a two-stage injection system, with a screw and barrel to do the melting and mixing of the material and a second stage dedicated to precise dosing control.

Because micro-molded parts are very small, often with intricate geometries, even minor changes to the process can have a dramatic impact on the quality of the finished part. Creating parts with wall thicknesses as low as 0.007 inches (0.18 mm) and holes as small as .004 inches (0.10 mm), micro part manufacturing can maintain dimensional tolerances of ± 0.0002 inches (±0.005 mm).

DPI’s team of knowledgeable engineers and technical representatives work closely with customers, assisting them with design for manufacturing, process validation, precision micro-molding, micro-digital manufacturing and value-added services, such as assembly and packaging. Common micro-molding materials include ABS, PEEK, PP, LCP, PET, PPS, PBT, POM, PEI, TPU, PPS, PPA, PSU, PC and PMP. ISO 13485 and 9001 certified, our facilities includes a class 8 cleanroom dedicated to micro-molding.

Micro-molded parts are extremely small, and the process demands extensive attention to quality control. DPI’s quality control team and processes ensure that parts are consistently made to specification. A robust quality control, inspection and measurement process is planned during the design for manufacturability phase. Verification of tool and finished part dimensions are completed using high-magnification microscopic measurements. After the part is complete, DPI provides value-added services, including packaging, to ensure that intricate parts arrive undamaged.